Shipping is no longer a back-office cost line you set and forget. In 2026, delivery is a conversion lever, a margin risk, and a customer experience promise in one. With 61% of shoppers saying they would switch retailers after a failed delivery, your shipping strategy should be a top priority.

In this guide, we’re sharing expert insights and breaking down what single-carrier setups quietly expose you to, why flexibility matters more than ever, and how to build a multi-carrier strategy that works end-to-end. Let’s get right to it.

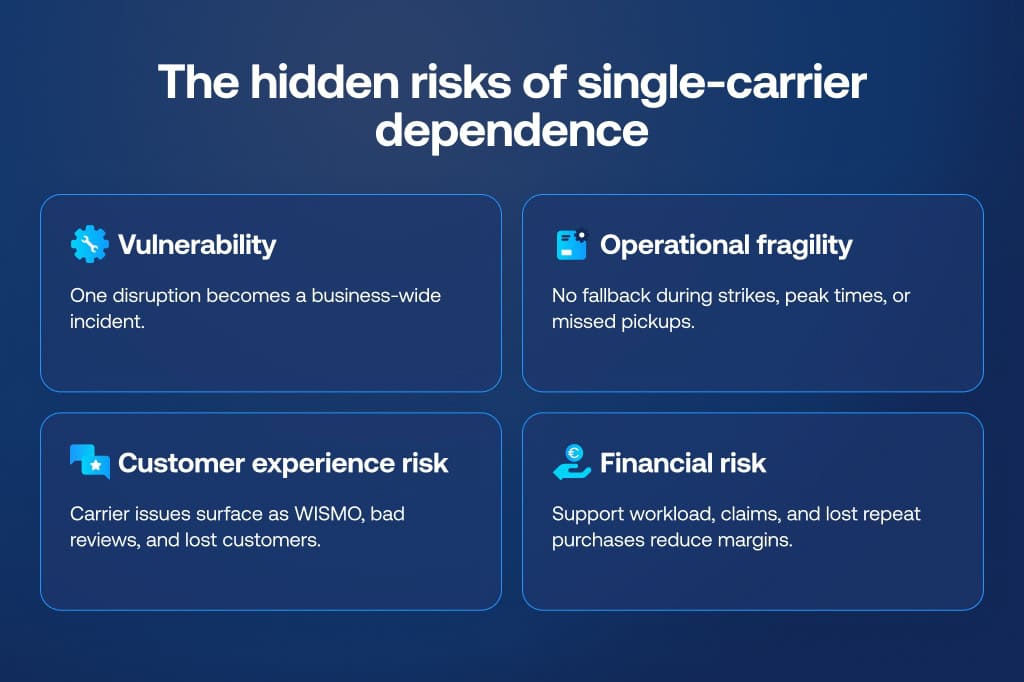

The hidden risks of single-carrier dependence

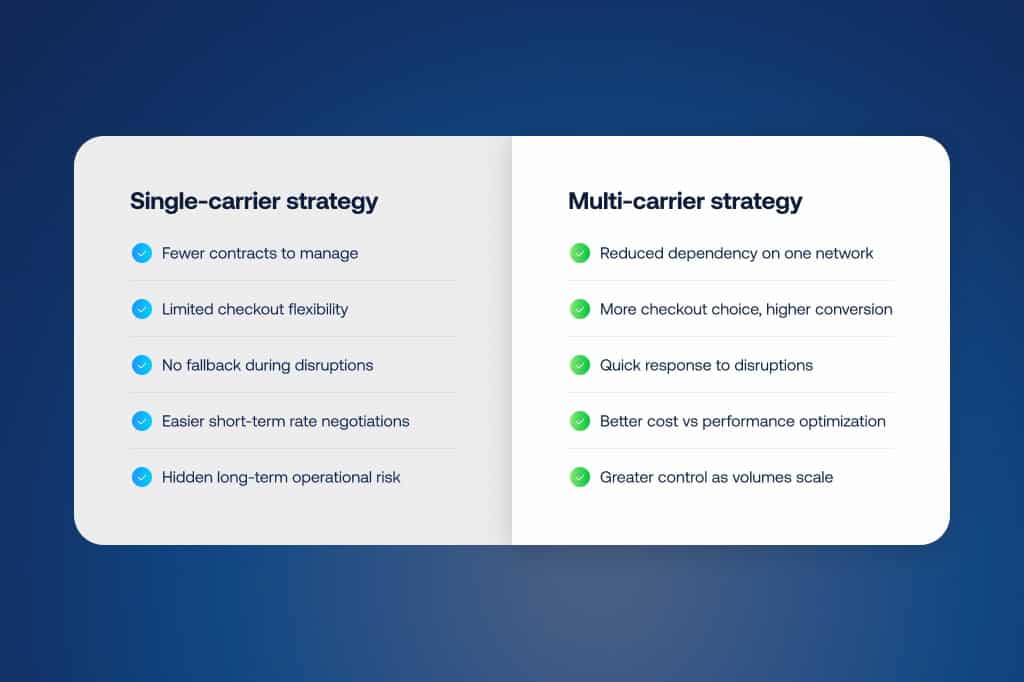

Still too many online retailers choose internal convenience over customer experience. From a business perspective, this totally makes sense. You’ve got fewer contracts to negotiate, less technical integrations and reduced warehouse complexity. It almost sounds like a no-brainer to stick to shipping with a single carrier. Especially if this has been a successful strategy for your business.

But, sticking to a single-carrier strategy is a fragile setup. Here are 4 serious risks that compound when volumes grow:

- Vulnerability: A single carrier reduces short-term complexity, but it concentrates risks. When your whole shipping operation depends on one network, one disruption is enough to have a negative impact on delivery and your customer experience.

- Operational fragility: Strikes, peak pressure, or a carrier simply missing a pickup are not edge cases. They happen. And when all your volume sits with one carrier, parcels stop moving. There is no quick fallback, and delays stack up fast.

- Customer experience risk: Late or failed delivery turns into complaints, bad reviews, lower trust and more work for your customer service team as well. And even before they decide to order in your store, 21.9% of shoppers say they would abandon their checkout if convenient delivery options are missing.

- Financial risks: Besides your shipping rates, more “Where is my order?” (WISMO) questions, manual claim handling and returns, but also missed repeat purchases add up quickly. Any rate savings disappear quickly when delivery performance drops.

The impact of carrier flexibility on checkout conversions

The checkout is the first visible touchpoint between your customer and your delivery strategy. And it’s exactly where that strategy starts to pay off or work against you. Maximum flexibility means giving shoppers control over how, where, and with which carrier their order is delivered.

That flexibility has a direct impact on conversion. Brands that introduce multiple carriers and delivery options often see a 20-30% increase in checkout conversion, equivalent to a 2-4 percentage point uplift. The effect becomes even stronger when shipping internationally, where expectations and preferences vary widely.

Free vs fast: the status quo in 2026

Most shoppers still prioritize cost over speed. While fast delivery matters, free or low-cost options remain the preferred option. 66.3% of customers abandon carts due to high shipping fees. 78.5% of consumers globally even prefer cheaper delivery fees, even if it means waiting longer.

But focusing only on price or speed misses a bigger shift. Data increasingly shows that delivery flexibility matters even more than speed and cost. Our Peak Season Index 2025 shows that for 63% of shoppers multiple delivery options matter more than fast delivery. For 72%, delivery needs to fit around their daily routine.

This is exactly where carrier flexibility pays off. It allows you to combine a free or low-cost option with faster, paid alternatives, instead of forcing a single trade-off on every customer.

European differences

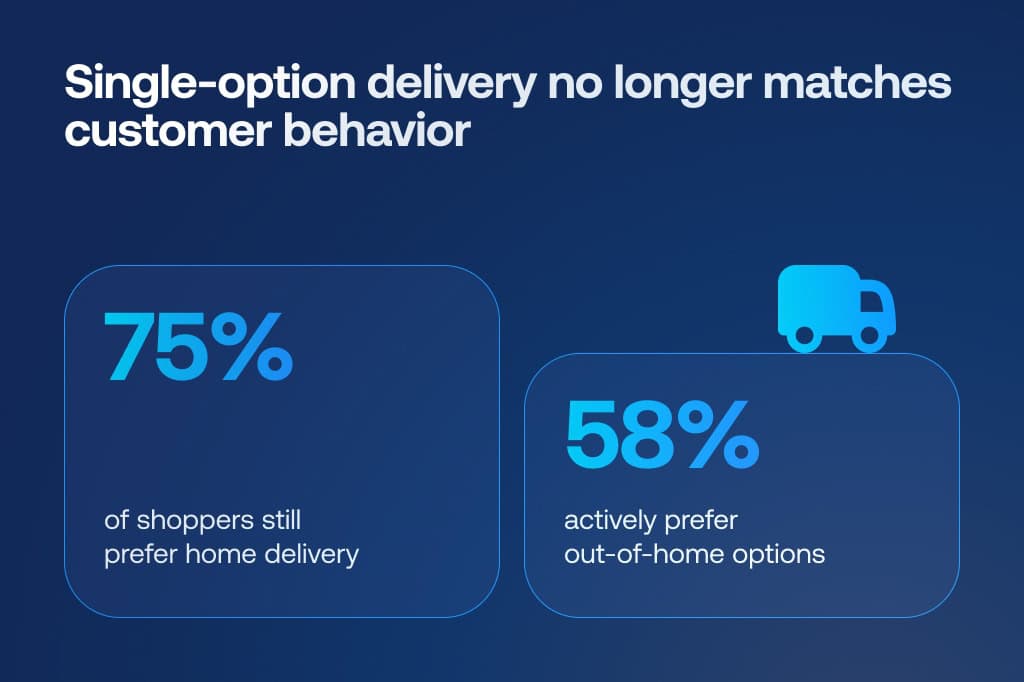

Delivery preferences vary significantly across Europe, which makes a one-size-fits-all checkout risky. While 75% of shoppers still prefer home delivery, 58% actively prefer out-of-home (“OOH”) options such as pickup points or parcel lockers.

Parcel lockers are gaining traction across Europe, with adoption nearing home delivery levels in the Nordics. This shift is expected to accelerate in other markets as well. Service points dominate in France and the Netherlands, while trusted national carriers like DHL play a decisive role in Germany. Speed expectations also differ per market, with shoppers in Germany and Spain generally being less patient.

A flexible checkout removes friction by letting customers choose what works for them, instead of forcing everyone into a single delivery option that only fits part of the audience. Meeting these preferences will decrease checkout abandonment rates. And let’s not forget about the fact that out-of-home delivery has higher delivery success rates and lower last-mile costs too.

From a conversion and cost perspective, offering multiple carriers or at least delivery methods might make complete sense. But one thing that’s holding many operations managers back when it comes to shipping with more than one carrier is warehouse operations.

Optimizing warehouse operations

More carriers obviously means more complexity. You need multiple sorting lanes and separate cages or pallets per carrier. If processes aren’t clear, parcels might end up on the wrong trailer. But it doesn’t need to be a hassle. Most issues only arise when warehouse teams are brought in too late or when carrier decisions are made in isolation.

Multi-carrier shipping works best when warehouse constraints are part of the decision from day one. Here are a few other tips that’ll help you set up for success:

- Limit complexity: Many retailers successfully work with 3-4 carriers per warehouse. Clear sorting rules based on carrier, parcel size, or cutoff time help prevent mistakes on the floor. Visual cues, dedicated lanes, and simple scanning checks go a long way in keeping parcels on the right path.

- Have a backup plan available: When a pickup is missed or a carrier is overloaded, having a second or third carrier already live allows teams to reroute volume within one or two days max. This becomes increasingly valuable as volumes grow.

- Align warehouse teams with customer-facing teams: Support teams often see delivery issues first. Warehouse teams control execution on their end. Sharing feedback on carrier performance helps refine sorting rules, carrier mix, and daily workflows. Strong collaboration is what turns multi-carrier shipping from a liability into an operational advantage.

With warehouse complexity under control, the real value of multi-carrier shipping comes from how you design your carrier mix.

The right carrier mix: balancing cost, speed, and reliability

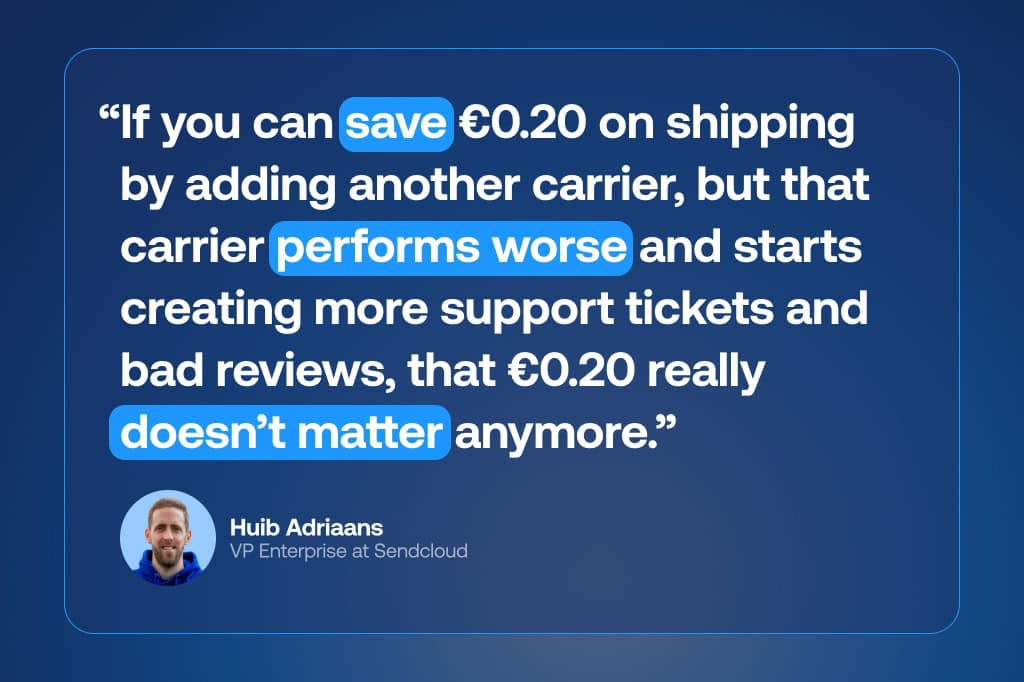

Choosing the right carrier mix is rarely about finding the cheapest rate. It’s about understanding the total cost of shipping, not just what you pay per parcel. If you ship with a carrier and save €0.20 on rates, but this carrier delivers less reliably, it can quickly become a very expensive parcel.

You need to take into account the chances of delivery delays, resulting in higher WISMO volume. But also manual claims handling, and lost repeat purchases. At scale, those hidden costs outweigh any rate advantage.

Data-driven carrier evaluation

The right carrier mix should be built on data. Don’t judge carriers on a bad week or sales pitch, but look at performance over time. Compare transit times, exception rates, delivery success, and even regional performance per lane.

Want to test the impact of adding another carrier to your portfolio? That doesn’t need to be difficult at all. Shift a small share of volume for a few months and measure results before making larger changes to your strategy. This allows you to balance risk and get real insights into which carrier performs best for what parcel types, destination and service levels.

With Shipping Intelligence you get the data to benchmark performance, which also helps to increase negotiation power. By combining the right carriers for your business, you’re able to optimize cost, speed and reliability at the same time.

But what if something happens and you ship with multiple carriers? Let’s have a look at the impact of carrier choices on support and how to optimize for that.

The impact of carrier choices on support

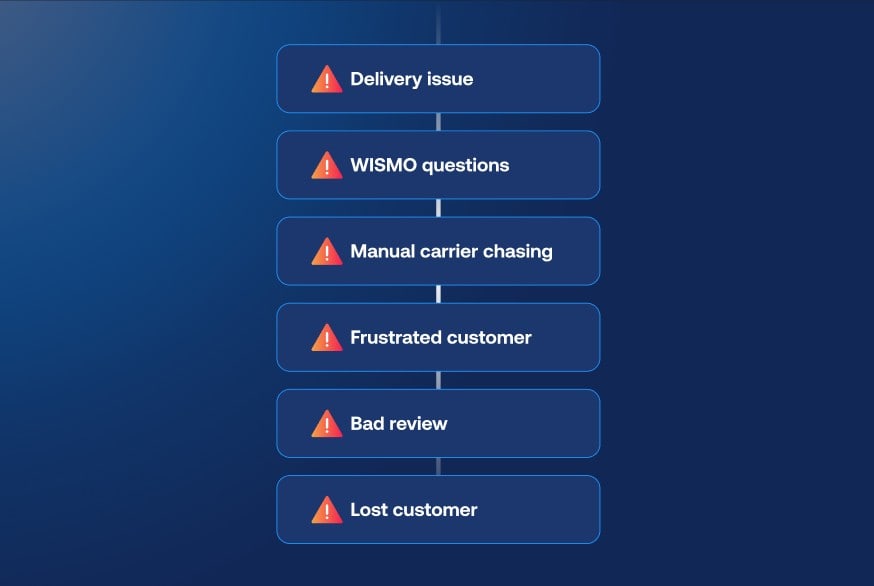

The impact of carrier performance on customer support is often underestimated. Fact is, less reliable carriers generate more delivery exceptions. Unfortunately, every exception triggers work downstream. More WISMO questions, more manual follow-ups with carriers, more refunds, and more frustrated customers.

Support teams often feel the consequences of carrier decisions first. WISMO questions aren’t a sign your customers are impatient. It’s a sign that expectations were misaligned or that delivery performance is inconsistent.

The good news is that you can still take ownership of delivery exceptions and create positive customer experiences.

Optimizing support workflows

You might not expect it, but multi-carrier setups can reduce workload for your support team when combined with standardized workflows and unified tracking. When tracking events are standardized across carriers, issues can be detected early. This allows teams to communicate proactively instead of reacting to tickets.

Curious to learn how that works? Here’s what a multi-carrier shipping platform, such as Sendcloud, can do for you in terms of optimizing support workflows.

- Centralized claims in one overview. Instead of jumping between carrier partners, you report issues, submit claims and track every ticket across your carriers in a clear overview.

- Automated issue detection. The system monitors every shipment’s tracking events. You get real-time visibility across shipments, spot delays early, and automatically update your customers. A parcel loss, delay, or damage is detected and a claim will be generated with the correct carrier.

- Carrier-specific rules are handled for you. By keeping deadlines visible, pre-filling forms with data from orders and prompting if photos or documents are missing your team doesn’t need to waste time on any claim handling.

- Track progress and recover refunds faster. Claims don’t disappear into an email thread. The software logs carrier replies, reminders, and outcomes, making it easy to see which claims are still open and which have been paid.

All of this sounds great on paper. But carrier flexibility, automation, and data only work if the underlying integrations can actually handle the complexity.

Technical integration and architectural considerations

We said it before, dealing with a single carrier is easier and could make sense from an IT perspective too. You only have to deal with one API, one label format, one tracking model. But convenience doesn’t scale and here’s why:

- Each additional carrier introduces its own API logic, label specifications, tracking events, and change cadence.

- APIs change, error codes evolve, and new shipping services need to be implemented and tested

Direct integrations come with hidden costs and risks. Missed API updates, delayed tracking events, or broken label logic can quickly make an impact. At scale, the cost of maintaining reliability often outweighs the perceived savings of building in-house.

Choosing a platform vs. building in-house

In the end it comes down to two options. You can build and maintain direct carrier connections yourself, but it asks for scarce engineering capacity on carrier plumbing, instead of core product development. A centralized delivery management software solution unifies carrier differences and tracking statuses, but also takes care of ongoing maintenance.

“Before Sendcloud, adding a new carrier could take days of development. Now we’re set up in just two to three hours, including testing.”

Every additional carrier introduces more complexity and its own API logic. APIs evolve, error codes change, and new shipping services need to be implemented and tested.

A single integration will unify carrier differences and tracking statuses, take care of ongoing maintenance and continuously optimize shipping processes.

Compare the best multi-carrier platforms here!

Implementation roadmap: build a resilient multi-carrier strategy

E-commerce is always evolving and the times when shipping was just a hygiene factor have long gone. You need to offer the best customer experience in order to make customers happy and increase chances they’re coming back. Implementing a multi-carrier strategy should be at the top of your list, if it isn’t already.

While it can feel like a hassle to implement, it doesn’t really need to be. Here’s an easy-to-use roadmap to strategically plan your multi-carrier shipping setup.

1. Assess current risks and bottlenecks

Map where your carrier dependency creates exposure today. Look into delivery failures, peak-season pressure, missed pickups, support ticket volumes, and IT maintenance effort. Forecast your shipping volume and decide whether your current carrier setup is ready for the future.

2. Start with your customer in mind

Will you enter new markets? Do you plan to sell different types of products? These decisions influence what customers are expecting. Prioritize customer preferences over internal convenience. Then decide upon free vs. fast, home vs. out-of-home or ideally both, and preferred carriers across regions.

Make sure consumer preferences and insights guide your next decision. Want to know more about what shoppers prefer per market? Our E-commerce Delivery Compass is here to help.

3. Define the right carrier mix

Defining the right carrier mix only works if you can see beyond isolated metrics. With Shipping Intelligence you can evaluate carriers based on how they perform in real conditions. Make sure to compare delivery performance, transit times, exceptions, returns and costs.

By using benchmarks, you can discover how your carriers perform relative to similar shipments across the Sendcloud network. This allows you to assign the right carrier to the right parcel and destination, shift volume away from underperforming carriers, test new carriers with success criteria and increase negotiation power with data.

The goal is to balance cost, speed and reliability, not purely optimize for rates.

4. Run a pilot and measure over time

When testing new carriers, you don’t want to switch everything at once. Introduce an additional carrier on a limited volume basis and monitor results. You need to give carriers a fair amount of time, so make sure to run a test for at least a whole quarter.

During this quarter you can measure transit times, delivery success rates, exceptions, conversion impact, and support workload. Get insights on trends rather than a single bad week.

5. Choose an infrastructure that scales

Ensure your technical foundation can support implementing multiple carriers, without IT being a bottleneck. Adding new shipping methods to your checkout or implementing new carriers shouldn’t break any processes. With delivery management software that offers a centralized carrier integration you reduce capacity needed from your engineering team.

6. Implement proactive communication with your customers

Ready to ship with multiple carriers and even diversify your strategy over multiple countries? Then make sure you have access to standardized tracking statuses so you can detect delays and shipping exceptions early. By knowing exactly what’s happening to each parcel, you can proactively inform customers before they are aware something is off.

Want to take full charge of shipping issues? Then standardize claim processes and issues handling across carriers with Support Automation. This reduces WISMO, lowers support costs, increases refunds and protects both customer trust and your margins when things go wrong.

Turn shipping into a competitive advantage at scale with Sendcloud

Shipping parcels might be one of the most frustrating parts of your operations. We get that. That’s exactly why Sendcloud has been built for this challenge since 2012. It’s time to take back control of the customer experience and stop letting delivery be the reason for 1-star reviews.

Reliable carrier connections are only one part of the equation. With Sendcloud Enterprise, the entire delivery journey is connected. From conversion-driving checkout options to international label creation, a broad portfolio of 160+ carriers, unified carrier data and intelligence, and automated claims handling.

Say goodbye to complex logistics processes and let us help you gain control over every step of delivery. Request a free demo and our shipping experts will show you how to reduce complexity, optimize logistics, save costs and consistently deliver on customer expectations.

Multi-carrier shipping FAQ

What is multi-carrier shipping?

Multi-carrier shipping means using more than one shipping carrier (e.g., DHL, DPD, UPS, GLS, PostNL, Colissimo) and choosing the best carrier per shipment based on factors like destination, delivery speed, cost, parcel size, and reliability.

Instead of relying on one carrier for all orders, you build a flexible setup that helps protect delivery performance across markets.

Why is multi-carrier shipping important for European e-commerce?

European e-commerce is complex because customer expectations and carrier performance vary by country and region. Multi-carrier shipping helps you:

- Reduce delivery risks during strikes, peak seasons, and missed pickups

- Offer better checkout delivery options (home + out-of-home)

- Improve conversion by matching local preferences

- Protect margins by avoiding WISMO spikes, claims, and refunds when delivery performance drops

What are the risks of using only one shipping carrier?

A single-carrier setup can look simple, but it increases risk as you scale. Common downsides include:

- No fallback option if the carrier is delayed or overloaded

- Higher WISMO volume (“Where is my order?”) when service drops

- Lower checkout conversion if customers don’t see their preferred delivery method

- Hidden costs from claims handling, failed deliveries, and lost repeat purchases

How does multi-carrier shipping improve checkout conversion?

Multi-carrier shipping enables more delivery options at checkout, such as:

- Standard vs express shipping

- Home delivery vs pickup points (OOH)

- Preferred national carriers per region

This reduces checkout friction and helps customers choose what fits their routine—leading to higher conversion and fewer abandoned carts.

What’s the difference between multi-carrier shipping and multi-method delivery?

They’re related, but not the same:

- Multi-carrier shipping = multiple carrier partners (e.g., DHL + DPD + UPS)

- Multi-method delivery = multiple delivery methods (e.g., home delivery + pickup points + lockers)

The strongest strategy combines both: multiple carriers + multiple delivery methods, especially across Europe.

How many carriers should an e-commerce business use?

There’s no universal “best number,” but most enterprise businesses aim for a core set of 3–6 carriers per warehouse or region, with additional specialists where needed (e.g., express, bulky, cross-border, lockers/OOH).

The goal isn’t to maximize carrier count—it’s to build resilience + performance coverage without adding unnecessary operational complexity. A solid enterprise setup typically includes:

- Primary carrier(s) for the majority of volume

- Secondary carrier(s) for peak capacity and service recovery

- Specialist carriers for specific lanes (e.g., premium express, returns, heavy parcels, remote areas)

- OOH coverage (pickup points / lockers) depending on market expectations

Most importantly: your carrier strategy should match your network design (countries shipped to, service promises, cutoff times, warehouse routing) and be reviewed quarterly using performance and exception data.

How do you choose the best carriers for multi-carrier shipping?

The best approach is data-driven carrier evaluation, using metrics like:

- Delivery success rate

- Transit time performance

- Exception rates (delays, damages, failed deliveries)

- Regional performance by lane (country/zip level)

- Support impact (WISMO + claims volume)

Instead of switching everything at once, many teams run a pilot test by moving a small percentage of shipments to a new carrier.

Why does multi-carrier shipping matter more for cross-border delivery?

Cross-border shipping adds complexity because preferences and “best-performing” carriers differ by market. Multi-carrier shipping lets you:

- Offer country-specific delivery options

- Use strong national carriers where trust matters

- Reduce delays caused by weak cross-border networks

- Adjust delivery promises without rebuilding your whole setup

How do you implement multi-carrier shipping step-by-step?

A practical roadmap looks like this:

- Identify your current single-carrier risks

- Map customer delivery preferences per market

- Define your target carrier mix (home + OOH)

- Run a pilot for at least a quarter

- Standardize your shipping and support workflows

- Use tracking + automation to communicate proactively

This approach helps you scale with less operational chaos.