Order fulfilment is incredibly time consuming and can contain some of the most labor-intensive and tedious tasks. In this article, we cover strategies to create a fast and effective order fulfilment process that will heavily improve your customer satisfaction rate and keep them coming back to your store.

Why is order fulfilment important?

In today’s market, a fast and effective e-fulfilment process is detrimental in determining the success of your online business. Customers now demand a state of the art experience, especially when compared to the services provided by giant e-tailers like Amazon.

However, in PeopleVox’s E-Commerce Fulfilment Report, they found 63% of businesses admitted to not always shipping on time, with 34% citing unavailability of stock as one of the key reasons for this.

Shockingly, 1 in 5 businesses also admitted to not knowing the cost of their shipping mistakes. However, Multichannelmerchant estimated that just one order fulfilment error can cost between €32 – €45 ($35 – $50), risking tens of thousands in unnecessary costs if you ship several hundred packages a month.

Effective order fulfilment isn’t just crucial for your customers’ happiness, but it also is paramount for you to reduce manual input and mistakes, save time and money, and continue to scale your business successfully.

The challenges retailers face with order fulfilment:

Before you begin, it’s good to complete an audit of your current order fulfilment process. Decide which areas of your workflow are causing the most issues and are preventing your business from shipping orders quickly and without mistakes. Then you can work towards fixing them!

Having trouble identifying what’s causing your bottlenecks? Check out the data we suggest tracking in the next section. It might help reveal where your issues are coming from.

Common challenges that hold back many businesses with efficient order fulfilment usually fall into the following categories:

- Demand planning (including stock outs or excess stock)

- Inventory management and communicating stock levels

- Supply chain execution, including being unaware of the time-frame it takes to re-order stock

- Picking and packaging

- Delivery and collection

- Returns, including both the customer’s process and handling incoming returns

Data Tracking: Key Metrics for improving your order fulfilment

Collecting data becomes more and more powerful over time as your order history grows. It can help you discover trends, common delays or mistakes, and clearly give you a direction in optimising your efficiency.

It’s also helpful to measure the effectiveness of your implement changes, clearly demonstrating the differences between before and after.

We highly recommend tracking the following metrics:

- Order fulfilment cycle time – this is arguably the most important metric to track. The overall goal is to reduce your fulfilment cycle time as much as possible while still ensuring a high standard of service. We explain how to calculate it below!

- Percentage of on-time shipments

- Average delivery time

- Fulfilment cost (per order)

- Order error rate

- Inventory turnover – Another important metric to track for good demand planning and efficiency of procurement. Calculate it by dividing the cost of goods sold by the average inventory level.

- Return rate

- Returns processing – What does it actually cost your business to process a return (money and time)?

- Customer retention rate

- Customer satisfaction levels

How to calculate your order fulfilment cycle time?

Your order fulfilment cycle time is the time it takes you to fulfil an order. Calculating it gives you a tangible, measurable index to track the improvements to your overall workflow, demonstrating if you’ve actually increased your efficiency.

A common formula used to calculate the order fulfilment cycle is: Total order fulfilment cycle time = Source time + Production time + Delivery time

- The source time: From the moment the customer makes an order online to the moment your business recognises that it has the correct raw materials/products available and in stock to start the order.

- The production time: The amount of time it takes to manufacture, finish, and pack the order. If you do not manufacture your own products, then this is just the time it takes to pick and pack the products.

7 clear strategies to improve your order fulfilment

Now you’ve considered what challenges are holding you back and decided how you will track and measure your order fulfilment cycle’s progress, it’s time to make the improvements that will help increase your efficiency.

Below are 7 different strategies to consider implementing, but you might not be able to complete all of them at once. Analyse your metrics and use your personal experience to decide which of the below strategies will make the most significant improvements to your efficiency. It’s also highly advisable to research and consider the costs (including time and human resources) of the following strategies before you start. Then you can decide which ones your business can feasibly implement.

Remember – the goal is to reduce your cycle time as much as possible without decreasing your standard of service!

1: Manage inventory accuracy

You can guarantee your customers won’t be happy if they order from your store to only find out their product is actually out of stock and they will have to wait. This is why inventory management is crucial to your order fulfilment process. Executing real-time cycle counts and syncing current stock levels to your store will ensure customers can’t order out-of-stock products. But this isn’t something you can do manually.

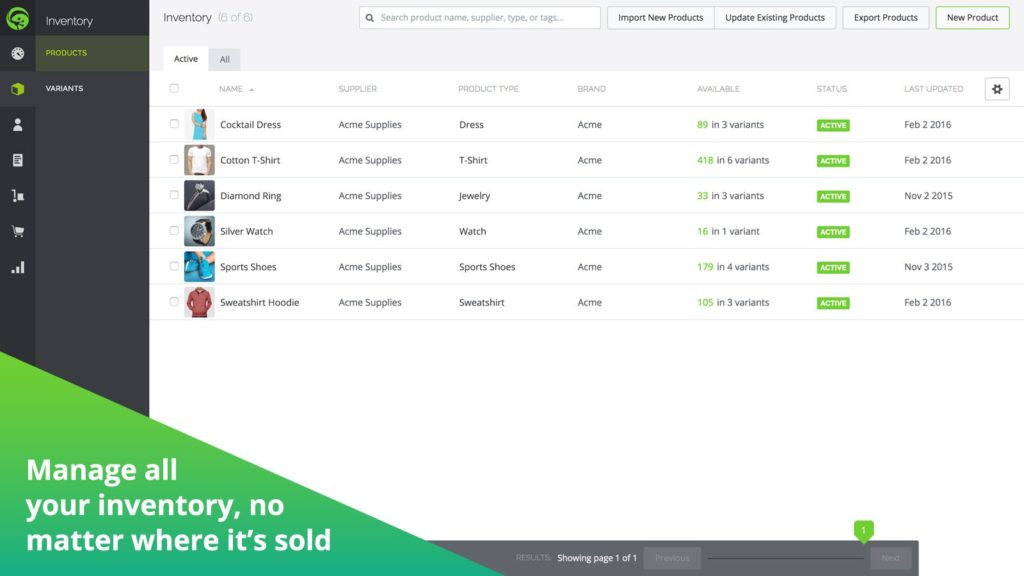

This is why you need to implement effective inventory management software. It’s advisable to start with a system that will easily integrate with your online sales platform without requiring a complex set up. An example of such software is Ecomdash. This allows you to manage your inventory across multiple platforms (like Shopify, Amazon, eBay, etc) with near real-time updates for an unlimited number of channels and manages product levels across multiple warehouses.

Before you choose an inventory management tool, make sure you research the features on offer and consider the following needs that your business might require:

- What are your inventory size and organisation method

- Are you a multichannel seller/do you have plans to be?

- Do you have multiple warehouses that need to sync collectively?

- Do you need the software to integrate and work cohesively with other tools?

- Can the tool scale as your store size grows?

Once you have a clear idea of what you need from an inventory management system, you can begin to research one that’s right for you. Some of our recommendations to look into (in no particular order) include: Fishbowl Warehouse, TradeGecko, DEAR Systems, Primaseller, and ZaoERP Inventory.

One step further:

Set up “back-in-stock” notifications to keep your customers excited and interested in your products. This is easily achieved with a simple plugin. For Shopify, you can choose plugins like Restocked Alerts Back in Stock by Booster, Alert Me! Restock Alerts by Dibble Development, and many more.

2: Automation: smart order processing

Order processing can be a huge block to improving your order fulfilment cycle time, and, as discussed, when done incorrectly it can result in a high order error rate (and high costs).

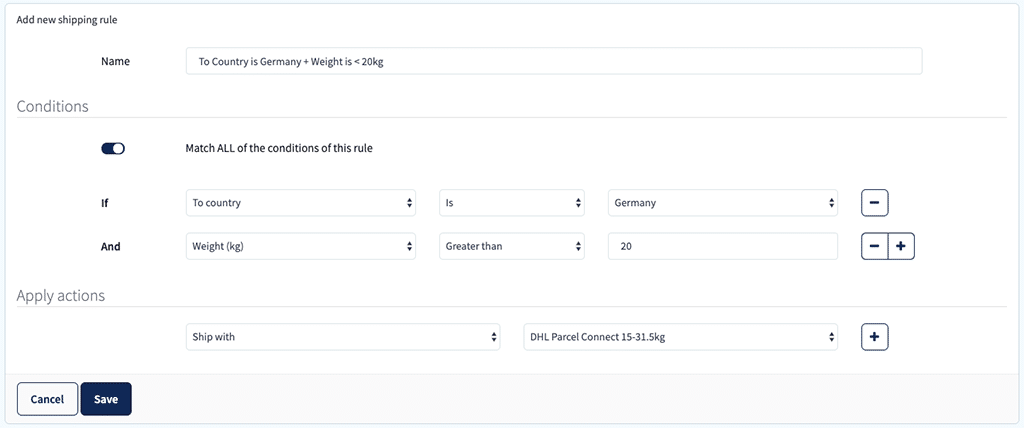

So how can you reduce your order error rate? By eliminating the need for manual, administrative changes in your order processing system. For example, maybe your employees currently have to change the carrier or shipping method if the package weighs more than a certain amount, or needs to be shipped internationally? There can be a multitude of scenarios in your order processing that rely on your employees manually making these changes to one order at a time. But this all costs time, and human resources.

Automating the process will eliminate this need for your employees to spend their time manually checking and adjusting each order. This can be achieved with Sendcloud’s Smart Shipping Rules. As an order is processed, the system will automatically apply the correct options by checking the determining conditions. This means all your employees need to do is pick, pack and send each order. Read more about automating your order processing here.

3: Warehouse organisation

Picking orders is the most labor-intensive job in the warehouse, with order pickers generally walking for 60-80% of their workday. Optimising your warehouse organisation can heavily increase your efficiency in picking and packing. It may take some time and trials, but the return on investment in time saved can be huge. Especially if it’s something you’ve not considered before!

So, how can you speed up the picking process without compromising on accuracy?

1: Re-organise your warehouse

“Slotting optimisation” is a method to manage the picking process in your distribution centres. It is the “process of determining where items should be placed in the picking area so that the popular items are stored close together and in close proximity to the starting point of picking to minimise walking time.”

But in order to do this, you need to know which products to place where. You can use the ABC Analysis to determine which products need to be placed close to your picking or packaging area.

The ABC Analysis is based on the idea 80% of your inventory movement (products that are sold and shipped the most) comes from just 20% of your overall stock. Therefore, it categorizes your stock into 3 categories:

A – This category contains the most profitable or most used items that account for 80% of total movement, or 20% of your total stock. These are your items that are ordered and shipped the most often. Category A stock should be placed for quick and easy access for the warehouse staff. If you can, store these items in easily accessible locations, closest to where they will be packed and shipped. And make sure there’s no need for your staff to bend, reach, or even need extra assistance to get to the products.

B – Second-best items accounting for 15% of the total movement, or 30% of total stock. As this stock will still be needed semi-regularly, it still ensures easy access. However, it does not need to be as closely located to the picking or packing stations.

C – Category C is the stock that doesn’t often move around the warehouse, accounting for 5% of movement but generally contains 50% of total stock. This means it can be placed the furthest away and can be stored in harder to reach areas.

2: Use picking technology or ERP systems

Implementing picking technology will also help streamline your picking process, helping your workers to move through the warehouse without wasting time.

Picqer is an example of such technology. Picqer creates batch picking lists from your orders that are based on the ideal walking route through your warehouse. This means your employees can efficiently pick the products without having to dart back and forth to reach the different products they have to get. Picqer also integrates with almost all barcode scanners. Barcode scanners can help the picking process, eliminating the risk of human error and considerably reducing the number of wrong products being picked and sent.

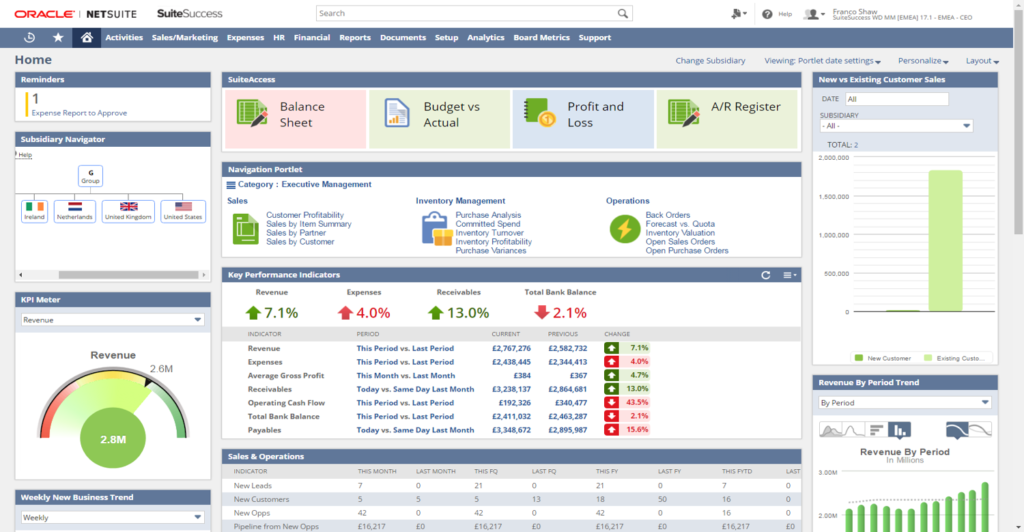

The next step would be to integrate an ERP system. If you don’t know what an ERP system is, it’s a centralised system that provides integration with all your major functions or information. Basically, it reduces the amount of administrative and operational costs by creating a centralised database. In e-commerce, it can be responsible for the most important processes, such as monitoring inventory levels, processing orders, optimising the shipping process, and providing comprehensive reports. Some of our top recommendations are SAP Business One, NetSuite ERP, Oracle ERP Cloud, and OneUp for smaller businesses.

And if you want to take it one step further and your budget allows, you can also consider adopting hand-held RF readers, pick-to-light systems, or voice picking systems in your workflow.

4: Improve Supplier Relationships and Implement Integration Tools

Whether you manufacture your own products with supplied raw materials, your products are manufactured elsewhere, or you order products in to resell, managing your supply chain cycle time is paramount. One key issue is the inability to track each process of the supply chain, including delays or holdups.

But supplier relationships can also have a significant impact. Almost 80% of businesses said that strong working relationships with suppliers deliver at least 25% greater value than poor relationships. Improving supplier relationships and integrating with them is a key strategy in having a clearer overview of your supply chain.

Steps to improving your relationship:

Consistent and transparent communication: Just like any part of life, communication is integral to keep things running smoothly. This helps to prevent errors, or missteps, like incorrect inventory count, missing purchase orders, or wrong invoicing.

Take responsibility for blame equally: An easy way to ruin any relationship is to start pointing fingers and avoiding tackling the issue together. When communication isn’t clear and dilemmas occur, it’s important to look at the situation from both sides of the transaction critically. Open a conversation around the issue and realise that both sides could be at fault and that a change in the process is likely needed. This helps show respect to your suppliers, translating to a better relationship and smoother future processes.

Know you aren’t the only client: Suppliers aren’t just working with your company, which means they may have a huge list of other businesses stressing the importance of their own needs. Of course, it’s important to assert priority to suppliers but aim to do this without over-communicating demands in a pushy manner. This type of mutual understanding will create a natural rapport and motivate suppliers to spend more time working with your company.

Create transparency through technology: Having the right tools in place will allow quick communication and make sharing documents and other information easy, helping facilitate a more transparent, even-sided conversation.

As CommerceHub describes: “A best-in-class platform integrates your suppliers’ order management system with your own so that missed orders, endless supplier coordination, invoicing errors and other such aggravations become things of the past.”

Using a fully integrated procure-to-pay system will enable access to real-time information that you would typically have to manually request from suppliers by email or phone. Technology also simplifies basic tasks like ordering more supplies and renewing contracts. Digitising key processes like these eliminates the chance of error and creates a satisfactory transaction system for both parties.

Some of our suggested tools to research include:

5: Offer a customer-centric delivery service

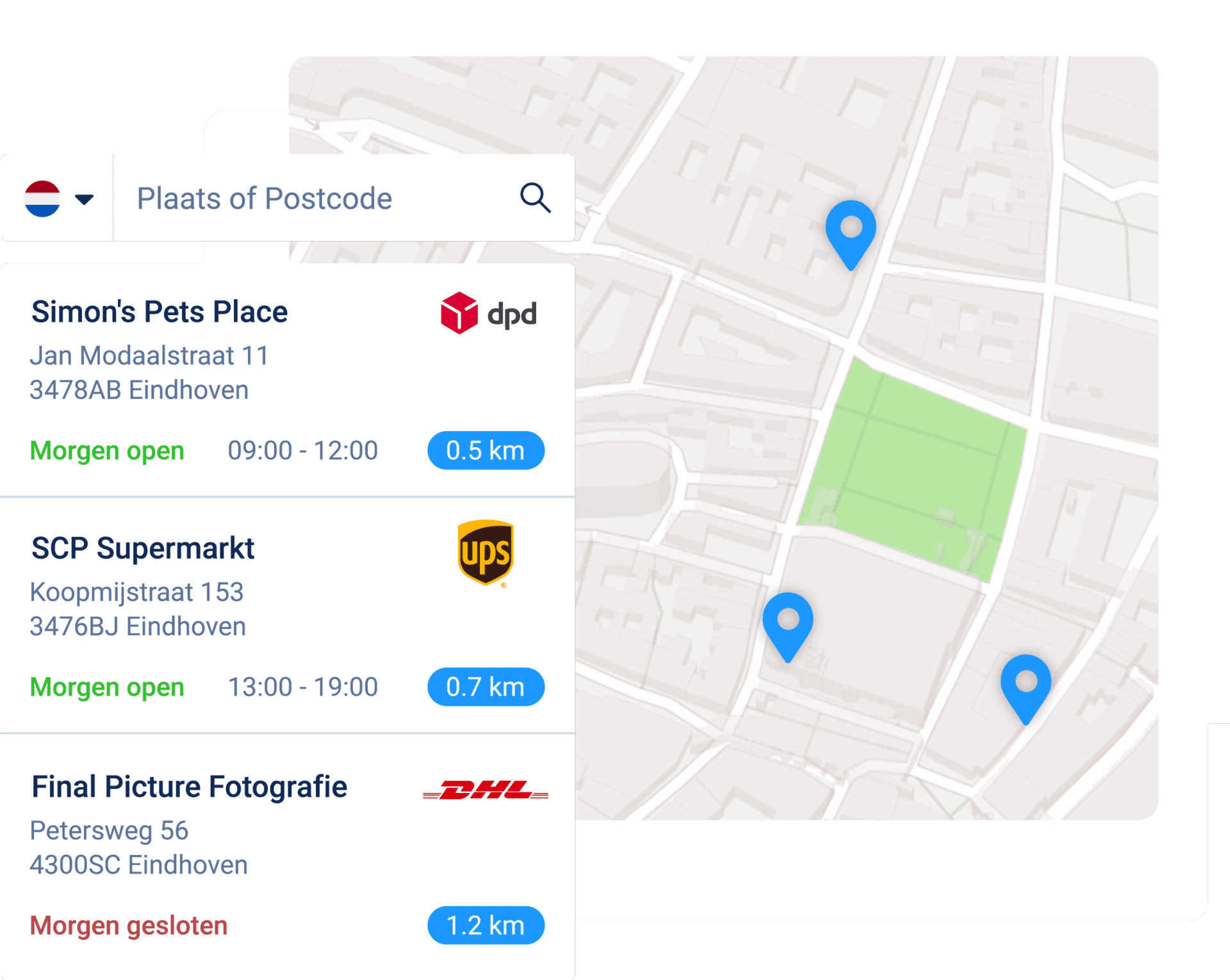

Customers want customisable, convenient delivery. Offering multiple carriers with different delivery services is the easiest way to do this.

Having access to multiple carriers isn’t just beneficial for your customers though. As a retailer, having the option to quickly switch carriers can relieve pressure during peak periods, alleviate disaster if your main carrier is unable to deliver your orders for reasons like a strike or other issues, and it can help you strategise your costs, sending certain pages (e.g. over a certain size or weight) with an alternative carrier if it is a cheaper option than your main provider.

Sendcloud offers the opportunity to easily integrate over 30+ carriers from across Europe, with multiple shipping methods, including integrating pickup points directly into your checkout.

6: Bring control and accuracy to your return process

For an effective and efficient returns process, it’s essential to know when a customer is making a return, why, and when it will arrive back at the warehouse. It’s also good to know, in advance, what actions will need to be taken for the customer (e.g. refund or exchange) and for you to get the product back on sale if possible (your returns process).

However, 42% of retailers say they aren’t aware of a return until it physically reaches the warehouse or returns processing centre, causing bottlenecks for the workers and costing time and money.

Automating your returns process with Sendcloud can help solve these issues. Firstly, our returns portal allows customers to arrange their return, supplying you with their reason, but also providing active tracking so you know exactly when the return will arrive back to your warehouse.

It’s essential to also make sure employees have a workflow that ensures the needed preparations can be made in advance of the return’s arrival, instead of having to deal with each return as they turn up. Sendcloud’s platform can centralise the processing of your returns all in one place, tracking incoming returns, meaning the necessary actions can be completed quickly and efficiently without wasting your workers’ time with manual adjustments or duplicate work.

Read more on our return’s solution to offer both a customer-friendly returns option and optimise your returns workflow to increase efficiency.

7: Smart Warehouse Systems

If you’re serious about being ultra-efficient and need to seriously scale-up your order fulfilment, then smart warehouse systems are something you should consider.

Smart warehouse systems utilise several interconnected technologies to boost efficiency, accuracy and they remove the need for human resources for those time-intensive tasks. These technologies include robotics, AI, warehouse management systems, radio-frequency identification (RFID – a digital barcode that uses radio waves), and the Internet of Things.

However, smart warehouse systems require a lot of investment, and that doesn’t just mean they cost a lot of money. You will likely need to employ the right staff to make sure the systems work best for your business, and they can take a while to properly implement into your process.

How are you currently improving your order fulfilment process? Have you managed to reduce your fulfilment cycle time? Let us know in the comments below, and share your best tips.

Want to know more about shipping with Sendcloud? Sign up for free now, and start optimising your shipping process straight away.