One mistake, many consequences.

Imagine your customer orders a phone case and receives a charger instead. A small mistake during packing suddenly turns into a refund request, a support ticket, and a disappointed shopper. Now multiply that by hundreds of shipments a day and it’s easy to see how misshipments become a silent profit killer in e-commerce.

As your business grows, these seemingly small errors add up. They drain time, increase costs, and impact customer trust. A significant 73% of e-commerce customers have reported receiving late or incorrect deliveries, and 23% of them stopped buying from that retailer altogether.

In this guide, we’ll break down what misshipments really are, why they happen, and how to prevent and manage them — without burning out your support team.

What is a misshipment?

A misshipment happens when a parcel is shipped incorrectly. That could mean:

- The wrong item was packed

- The right item was sent to the wrong customer

- An extra product was accidentally added

- A duplicate order was shipped twice

It’s not the same as a lost parcel or delayed shipment — the courier did their job, but what arrived at the customer’s door wasn’t right. And in e-commerce, that often leads to refunds, negative reviews, or lost customers.

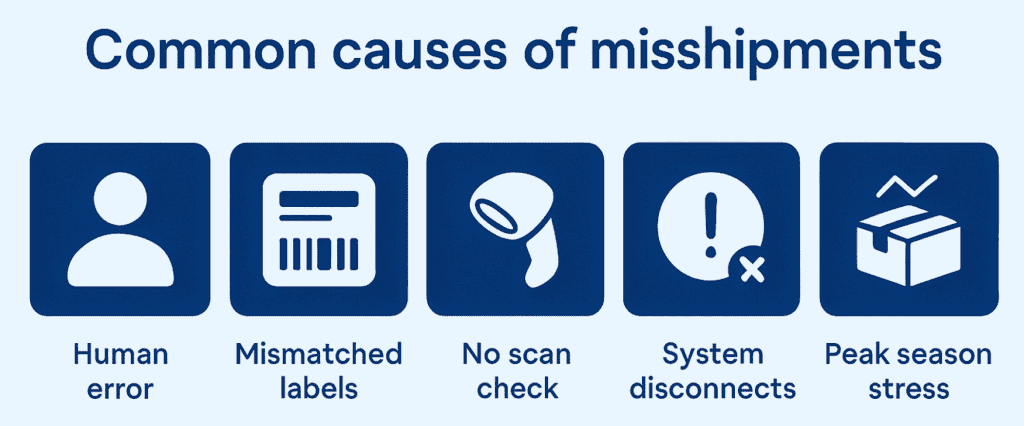

What causes misshipments in e-commerce?

They’re not random. Most misshipments follow the same patterns. And often, they’re preventable:

Human error during picking and packing

In fast-paced warehouses, it’s easy to grab the wrong SKU, scan the wrong barcode, or pack the item without double-checking. Rushed workflows during sales peaks make things worse.

Outdated or disconnected systems

If your webshop, warehouse, and shipping tools aren’t synced properly, small data mismatches can lead to big problems. For example: a label gets printed with the wrong customer info because the shipping rule wasn’t updated.

Lack of quality control

No final scan check? No one reviewing what goes into each parcel? That’s a recipe for errors. If you can’t track who packed which order, you can’t spot patterns or hold anyone accountable.

Poor team coordination

When warehouse, customer service, and operations teams aren’t aligned, things fall through the cracks. Different SOPs, unclear responsibilities, or untrained staff often lead to misshipments — and no one knows until the customer complains.

The cost of a misshipment

| Impact type | Example | Why it matters |

|---|---|---|

| Operational costs | Double shipping fees, return handling, repacking | Eats into your profit margins over time |

| Customer experience | Wrong item received | Breaks trust, leads to negative reviews and churn |

| Support team workload | Extra tickets, long resolution time | Slows down your team and increases CS stress |

| Lack of process insight | No root cause tracking or learnings | Leads to repeated errors without improvement |

5 practical ways to prevent misshipments

Misshipments aren’t always avoidable, but the right workflows and tools can make them rare. Here’s how to build more accuracy into your operations:

1. Use scan-based picking and packing

Tools like Sendcloud’s Pick & Pack help verify every item before it goes into the box. Each product is scanned and matched against the order. So wrong SKUs are flagged immediately. Bonus: it works even when your warehouse is under pressure.

2. Add a final scan check before handoff

Before printing the shipping label or handing off to the courier, do one last check:

- Does the item match the order?

- Is the destination address correct?

This simple step catches errors before they leave the warehouse.

3. Automate label generation and courier logic

Manual label printing = manual mistakes.

Set up smart shipping rules that auto-select the right courier, service level, and label — based on destination, weight, or SKU. This eliminates confusion and prevents labels being mixed up.

4. Track errors in a central log

When a misshipment happens, log it. Capture what went wrong, who handled it, and how it was resolved.

Over time, you’ll spot patterns — like one product being repeatedly mispacked — and fix the root cause.

5. Train (and retrain) your team

Your tools are only as good as the people using them. Create clear SOPs, train warehouse staff regularly, and keep everyone aligned — from operations to support.

What to do when a misshipment happens

Even with the best systems, mistakes happen. Here’s how to handle them professionally — and protect the customer relationship.

- Act fast: Don’t wait for the customer to follow up twice. Proactive responses go a long way.

- Log the issue centrally: Assign it to the right person and make sure it doesn’t get lost in someone’s inbox.

- Automate internal workflows: With tools like Support Automation, you can trigger ticket creation, track resolution status, and avoid delays.

- Resolve clearly: Offer a refund, reshipment, or store credit — and explain exactly what will happen next.

- Close the loop: Feed the incident back into your operations team so it doesn’t happen again.

If the issue results in a lost or damaged shipment, you might also need to file a formal claim with your courier. Here’s a practical guide to handling freight claims in e-commerce.

How automation helps reduce and resolve misshipments

Misshipments are caused by manual chaos. Automation brings structure, speed, and control.

Pick & Pack

Reduces human error by using scan-based order verification. It’s faster, more accurate, and works even during busy periods — no complicated setup needed.

Shipping Intelligence

Understand where things go wrong — and with whom. Use data to identify which products, couriers, or teams are linked to repeated misshipments. Then fix it. Check out Shipping Intelligence.

Support Automation

When things do go wrong on the courier’s side and result in lost or delayed parcels, support automation helps you act quickly and professionally — with fewer resources and a better customer experience.

Support automation centralises all delivery issue handling. You can:

- Detect errors early – even before your customers do. If a wrong parcel is reported as undelivered, your team can act fast.

- Automate claim creation.

- Track progress across your team.

- Keep customers updated without endless copy-pasting.

Misshipment prevention checklist

✅ Scan-based picking and packing process

✅ Final label check before courier handoff

✅ Automated label rules (no more manual printing)

✅ Central error tracking log

✅ Support workflows that scale

✅ Team SOPs and regular training

Conclusion: Misshipments are small mistakes with big consequences

In e-commerce, accuracy matters. A single misshipment can cost you time, refunds, and a customer’s trust. Manual fixes don’t scale, but structured workflows and automation do.

Whether you’re shipping a few hundred parcels or scaling into thousands, managing misshipments well is a sign of operational maturity — and the right tools can help you level up.

Curious how Sendcloud can help? Explore Support Automation by Sendcloud!